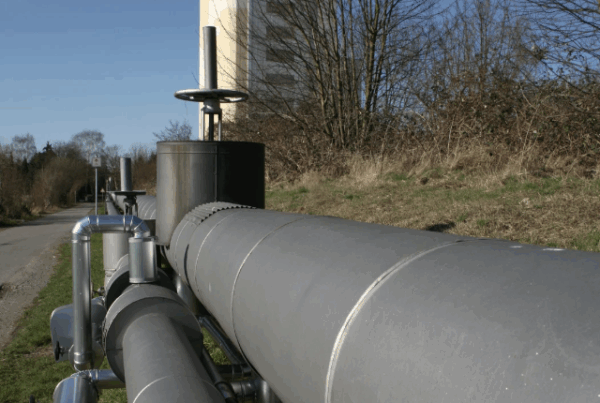

Pipeline failure is one of the most costly and disruptive challenges facing infrastructure managers today. With hundreds of thousands of water main breaks occurring annually in North America, understanding why pipelines fail isn’t just academic; it’s essential for budget planning and system reliability.

At Advantage Reline, after rehabilitating over 250,000 miles of pipelines, we’ve identified the primary culprits behind infrastructure failure.

This comprehensive guide explores the seven most common causes of pipeline failure, early warning signs, and proven trenchless solutions that can restore your system without the disruption of traditional excavation.

What Are 7 Leading Causes of Pipeline Damage?

1. Aging Infrastructure: The Silent Threat

Age-related deterioration affects millions of miles of North American pipeline infrastructure. With many municipal systems installed between 1950-1980, we’re now seeing widespread failure of pipes that have exceeded their design life.

Key statistics:

- Average water main pipeline lifespan: 75-100 years

- Percentage of US water pipelines over 40 years old: 43%

- Expected pipe replacement needs by 2035: $1 trillion

Materials like clay, cast iron, concrete, and steel naturally degrade over decades. Cast iron pipes, common in systems built before 1960, are particularly vulnerable to graphitization, a process where the iron matrix deteriorates, leaving only brittle graphite behind.

2. Corrosion: The Chemical Breakdown

Corrosion attacks both metallic and concrete pipelines through electrochemical reactions. This process creates pinholes, reduces wall thickness, and ultimately leads to catastrophic failure.

Types of pipe corrosion:

- External corrosion: Caused by soil conditions, stray electrical currents, or galvanic reactions

- Internal corrosion: Result of aggressive water chemistry, high chlorine levels, or low pH

- Microbiologically influenced corrosion (MIC): Bacterial activity that accelerates metal degradation

Corrosion rates vary dramatically based on soil resistivity, pH levels, and pipe material. Unlined cast iron pipes can lose 1-5 mils per year in aggressive environments.

3. Joint Separation and Seal Failure

Joint separation occurs when connections between pipe segments fail. This is especially common in:

- Bell and spigot joints with lead or oakum seals

- Mechanical joints with deteriorated gaskets

- Concrete pipes with mortar joints

Joint failures account for approximately 30% of all water main breaks and are the leading cause of infiltration and inflow (I&I) in sewer systems.

4. Ground Movement and Settlement

Soil instability creates external forces that pipelines weren’t designed to handle. Common causes include:

- Seismic activity: Even minor earthquakes can damage rigid pipe materials

- Freeze-thaw cycles: Frost heave can lift and crack pipelines

- Soil settlement: Uneven ground movement creates stress concentrations

- Construction activity: Nearby excavation or heavy equipment can shift pipe alignment

Clay soils are particularly problematic, expanding up to 10% when wet and contracting significantly during dry periods.

5. Pressure Surge and Water Hammer

Hydraulic transients create pressure spikes that can exceed pipe design limits. Water hammer events can generate pressures 5-10 times normal operating levels within milliseconds.

Common causes of pressure surge:

- Rapid valve closure

- Pump startup or shutdown

- Air release from high points

- Check valve slam

Pipelines operating near their pressure rating are especially vulnerable, and repeated pressure cycles can cause fatigue failure even in newer systems.

6. Root Intrusion and Blockages

Root infiltration affects both water and sewer lines, with tree roots seeking moisture and nutrients from pipe joints and cracks. Once established, roots can:

- Block flow capacity by up to 90%

- Create turbulence that accelerates corrosion

- Physically damage pipe walls through growth pressure

The problem is particularly severe in areas with large trees and older pipe materials.

7. Poor Installation Practices

Construction defects cause premature failure even in high-quality pipe materials. Common installation problems include:

- Inadequate bedding or backfill compaction

- Improper pipe support or alignment

- Damaged pipes installed without inspection

- Non-compliant joint installation

Studies show that installation defects reduce pipe service life by 25-40% compared to properly installed systems.

Early Warning Signs of Pipeline Failure

Recognizing failure symptoms early can prevent catastrophic breaks and minimize repair costs. Here are the key indicators infrastructure managers should monitor:

Visible Signs

- Surface water pooling in unexpected locations

- Pavement settlement or soft spots over buried pipes

- Vegetation changes (unusually green grass or stressed plants)

- Sinkholes or ground depression indicating soil erosion

Performance Indicators

- Pressure fluctuations during normal operations

- Flow capacity reduction without apparent blockages

- Increased pump runtime or energy consumption

- Water quality changes (discoloration, taste, or odor)

System Monitoring Data

- Rising water loss percentages in distribution systems

- Infiltration increases in sewer systems during wet weather

- Acoustic monitoring alerts from leak detection systems

- SCADA alarms indicating pressure or flow anomalies

Modern Trenchless Solutions for Pipeline Rehabilitation

Traditional dig-and-replace methods are no longer the only option for failed pipelines. Advantage Reline specializes in trenchless rehabilitation technologies that restore structural integrity and extend service life without the need for excavation.

Primus Line High-Pressure Rehabilitation

Primus Line technology handles pressurized systems up to 300 PSI using a flexible, high-strength liner that navigates bends and fittings.

Recent project success: Seattle Public Utilities – 1,800 feet of 75-year-old cast iron water main with 7 directional changes, renewed for 100+ years of service life.

Cured-In-Place Pipe (CIPP) Lining

CIPP rehabilitation creates a new pipe within the existing structure using resin-saturated felt liner that cures to form a seamless, corrosion-resistant interior.

This method restores structural integrity to meet ASTM standards, reduces infiltration by more than 95%, and provides a design life of 50 to 100 years. Additionally, CIPP lining achieves all of this with minimal surface disruption, making it an effective and efficient solution for renewing aging or damaged pipelines.

Ideal applications: Gravity sewer lines, storm drains, and low-pressure water mains

Spray-In-Place Pipe (SIPP) Coating

SIPP applications use robotic systems to apply protective coatings that stop corrosion and improve hydraulic capacity.

This method provides corrosion protection for over 50 years, increases flow capacity by up to 15%, and reduces friction within the pipe. All of these benefits are achieved with minimal system downtime, making SIPP an efficient and long-lasting solution for pipeline rehabilitation.

Fiber-Reinforced Polymer (FRP) Repairs

Structural FRP wraps reinforce damaged pipe sections and provide long-term strengthening for compromised areas.

Preventive Maintenance and Inspection Programs

Proactive pipeline management can identify problems before they turn into costly failures. By implementing regular inspection schedules and monitoring critical systems, infrastructure managers can extend pipeline life, reduce unexpected downtime, and prevent water quality issues.

Key preventive measures include:

Regular Pipe Inspection Schedules

- Video inspection: Every 5-10 years for critical mains

- Acoustic monitoring: Continuous for high-value assets

- Pressure testing: After any significant system changes

- Water quality monitoring: Ongoing for distribution systems

Condition Pipe Assessment Technologies

- CCTV inspection for internal condition evaluation

- Ground-penetrating radar for external pipe location and condition

- Acoustic leak detection for early leak identification

- Pressure monitoring for hydraulic performance tracking

Frequently Asked Questions About Pipeline Failure

How long do different pipe materials last?

Average service life by material:

- Cast iron: 75-100 years

- Ductile iron: 100+ years

- PVC: 100+ years

- Concrete: 50-100 years

- Clay: 50-75 years

What’s the most common cause of water main breaks?

Age-related deterioration combined with joint separation accounts for over 60% of water main failures in North America.

Can trenchless methods work on all pipe materials?

Most pipe materials can be rehabilitated using trenchless methods, though the specific technique varies based on diameter, pressure rating, and access constraints.

How do I know if my pipeline needs immediate attention?

Visible leaks, significant pressure drops, or sudden flow capacity reduction require immediate professional assessment.

Choose Proactive Pipeline Management

Understanding pipeline failure causes empowers infrastructure managers to make informed decisions about maintenance, rehabilitation, and replacement timing. With proper monitoring and modern trenchless rehabilitation techniques, most pipeline problems can be addressed before they become costly emergencies.

Ready to assess your pipeline condition? Advantage Reline’s certified inspection teams use advanced diagnostic equipment to identify problems early and recommend cost-effective solutions. Our trenchless rehabilitation methods have successfully restored over 250,000 miles of pipeline infrastructure with minimal disruption and maximum long-term value.

Contact Advantage Reline today for a comprehensive pipeline assessment. Let’s identify and solve your underground challenges before they surface as major problems.

About Advantage Reline: Leading provider of trenchless pipeline rehabilitation services across North America, specializing in Primus Line sliplining, CIPP lining, spray-in-place coatings, and high-pressure pipeline renewal. Serving municipal, industrial, government, and commercial clients since 2017.