If you manage a commercial, industrial, or municipal facility, chances are you’ve received a CCTV pipe inspection report at some point. These reports are often shared after backups, slow drains, or as part of preventative maintenance but for many facility managers, they can be difficult to interpret.

You don’t need to be a pipe expert to use these reports effectively. The goal isn’t to understand every technical detail, but to know what matters, what signals risk, and how the information can guide decisions about pipe relining or repair.

This guide breaks down how to read and use CCTV pipe inspection reports in a clear, practical way so you can make informed relining decisions without getting lost in industry jargon.

What Is a CCTV Pipe Inspection Report?

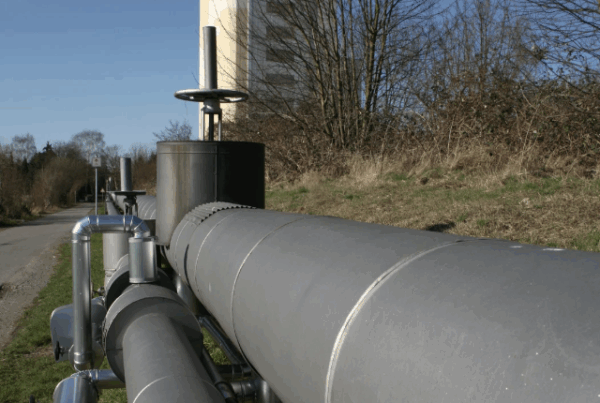

A CCTV pipe inspection report is created after a small camera is sent through a sewer or stormwater pipe. The camera records video of the pipe’s interior, allowing inspectors to document its condition without digging or disrupting operations.

The report typically includes:

- Video footage of the inside of the pipe

- Notes describing observed issues

- Locations of defects along the pipe

- Photos or screenshots from the inspection

For facility managers, this report acts as a snapshot of pipe health. It shows what’s happening underground and helps determine whether a pipe can continue operating as-is, needs maintenance, or should be rehabilitated through trenchless relining.

Why CCTV Pipe Inspection Reports Matter for Relining Decisions

Without inspection data, decisions about pipe repair or replacement are often based on assumptions… or worse, made after a failure occurs.

A CCTV pipe inspection report helps answer critical questions:

- Is the pipe structurally sound or starting to fail?

- Are issues isolated or recurring?

- Can the pipe be rehabilitated, or is replacement necessary?

For trenchless pipe relining decisions, inspection data is essential. Relining works best when the pipe still has basic structural integrity, and CCTV inspections help determine whether that’s the case.

Key Parts of a CCTV Pipe Inspection Report to Focus On

You don’t need to understand every line of the report. Instead, focus on these core areas:

Pipe Material and Size

The report will usually note what the pipe is made of (such as cast iron, clay, or concrete) and its diameter. This matters because different materials age differently, and some are more prone to corrosion or cracking.

As a facility manager, the key takeaway is whether the pipe material is known to deteriorate over time, which may make relining a strong long-term option.

Noted Defects and Observations

Inspectors document issues they see inside the pipe. These may include:

- Cracks or fractures

- Corrosion or surface deterioration

- Roots entering through joints

- Misaligned or separated pipe sections

You don’t need to memorize defect terminology. What matters is whether issues are structural (affecting pipe strength) or maintenance-related (blockages or buildup). Structural issues are often the strongest indicators that relining should be considered.

Location and Frequency of Issues

Most CCTV reports show where problems occur along the pipe. Pay attention to:

- Issues that appear repeatedly in the same areas

- Long sections with continuous deterioration

- Problems near joints or connection points

Recurring issues in the same locations usually indicate an underlying pipe problem rather than a one-time blockage.

Common Problems Identified in CCTV Pipe Inspections

CCTV inspections often reveal issues that aren’t visible from the surface, including:

- Internal corrosion in older metal pipes

- Cracks or deformation caused by age or ground movement

- Root intrusion entering through joints

- Water infiltration, where groundwater enters the pipe

These problems don’t always cause immediate failure, but they tend to worsen over time. Identifying them early allows facility managers to plan rehabilitation instead of reacting to pipe emergencies.

How CCTV Reports Help Determine If Pipe Relining Is the Right Solution

A CCTV pipe inspection report is one of the primary tools used to decide whether trenchless pipe relining is appropriate.

Relining is often a good option when:

- The pipe is deteriorated but not fully collapsed

- Problems occur along extended sections of pipe

- Excavation would disrupt operations or access

In contrast, full replacement may be necessary if the inspection shows complete structural failure or severe deformation. The report provides the evidence needed to make this call with confidence.

What Facility Managers Should Look for (Without Being Pipe Experts)

When reviewing a CCTV pipe inspection report, focus on practical questions:

- Are the same pipe segments flagged repeatedly?

- Are temporary repairs becoming routine?

- Does the report recommend further evaluation or action?

- Are issues described as worsening or ongoing?

You don’t need to interpret technical language, patterns and recommendations matter more than terminology. If a report highlights recurring defects or notes declining pipe condition, it’s usually time to explore long-term solutions like relining.

When to Involve a Trenchless Pipe Relining Specialist

If a CCTV pipe inspection report identifies structural issues or ongoing deterioration, it’s often helpful to involve a trenchless relining specialist. Our staff are certified through NASSCO’s BSDI Certification Program, ensuring they have the training and expertise to accurately assess pipe conditions. We can:

- Review inspection findings

- Confirm whether relining is feasible

- Help develop a phased rehabilitation plan

This step ensures that decisions are based on accurate interpretation of the inspection data and aligned with long-term infrastructure goals.

Turning CCTV Pipe Inspection Reports Into Smarter Relining Decisions

A CCTV pipe inspection report isn’t just a technical document, it’s a decision-making tool. When understood at a practical level, it helps facility managers reduce risk, plan budgets more effectively, and choose the right solution at the right time.

By focusing on recurring issues, structural condition, and long-term performance, facility managers can confidently use inspection data to guide trenchless pipe relining decisions and avoid costly surprises down the road.

Do you need a pipe inspection? Contact us to schedule a camera pipe inspection and evaluate your pipe infrastructure with confidence.