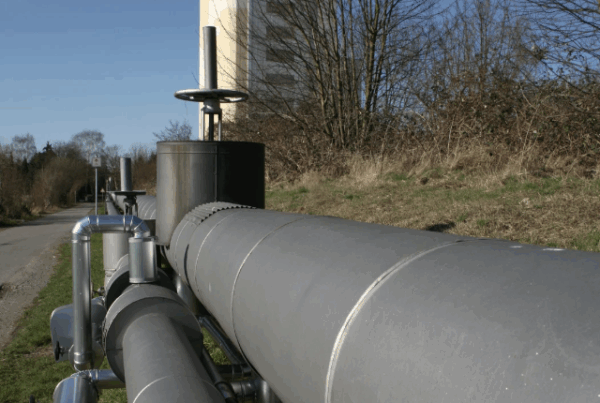

Dangerous gas leaks are more common than you might think. Every 40 hours, such an incident occurs somewhere in the United States. If you find one, you need to handle it correctly or you might become a statistic too.

In commercial or industrial facilities, gas leaks can cause serious incidents that endanger employees, disrupt operations, and result in costly damage. Proper emergency gas line repair and response are critical to ensuring safety, minimizing downtime, and maintaining regulatory compliance.

This guide outlines essential steps for handling a gas line emergency safely and effectively, emphasizing professional involvement and facility protocols.

Immediate Safety Measures

-

Evacuate and Isolate

-

Immediately evacuate the area surrounding the suspected gas leak.

-

Prevent unauthorized personnel from entering the affected zone.

-

Shut off the gas supply at the main valve if it can be done safely without risk of ignition.

-

-

Ventilate the Area (if applicable)

-

If safe to do so, open doors and vents to allow gas to disperse.

-

Avoid any activities that could produce sparks or flames.

-

-

Alert Personnel and Authorities

-

Notify facility management and emergency response teams.

-

Contact your gas provider and/or a certified gas line repair contractor immediately.

-

Professional Inspection and Repair

Gas line repair in commercial settings requires trained technicians with specialized equipment:

-

Leak Detection: Professional crews use electronic gas detectors, ultrasonic sensors, or infrared technology to locate the source accurately.

-

Assessment: Inspect the extent of damage, determine whether temporary containment is needed, and plan permanent repairs.

-

Repair Methods: Depending on the situation, professionals may use epoxy lining, pipe clamps, or replace sections of the pipeline. All work is performed following safety codes and industry standards.

Key Point: Attempting DIY repairs in commercial facilities is highly unsafe and usually violates regulatory requirements. Only certified professionals should perform these repairs.

Post-Repair Gas Line Verification

Once the repair is completed, it is essential to conduct thorough leak testing using specialized gas detection equipment to ensure the line is secure. The surrounding infrastructure should be inspected for any collateral damage that may have occurred during the leak or repair process. Additionally, all repair work should be properly documented and reviewed in accordance with facility protocols to maintain safety and regulatory compliance.

Why Professional Gas Line Repair Matters

Professional intervention is critical to ensure the safety of employees and visitors while minimizing operational downtime. Certified technicians follow all relevant safety and regulatory standards, providing a repair that is reliable and long-lasting. This approach reduces the risk of future leaks and helps maintain the integrity of your facility’s gas line system.

Protect Your Facility with Expert Gas Line Repairs

Gas leaks in commercial facilities are high-risk events that require immediate and careful action.

Always prioritize evacuation, isolation, and professional repair services over DIY methods. Properly handled, gas line emergencies can be contained safely, protecting employees, property, and operations.

Contact a certified gas line repair professional today to ensure your facility’s gas lines are secure and compliant.