When it comes to pipeline rehabilitation, one of the most important decisions municipalities, facility managers, and utility owners face is whether to repair, rehabilitate, or replace aging pipelines.

At Advantage Reline, we specialize in trenchless technology and advanced inspection methods that remove the guesswork. With services ranging from CIPP (Cured-in-Place Pipe) and SIPP (Sprayed-in-Place Pipe) to Primus Line® pressure pipeline rehabilitation, we help clients protect infrastructure and budgets while avoiding unnecessary excavation.

Pipeline Condition Assessment for Rehabilitation vs Replacement

Our process begins with a detailed pipeline condition assessment using digital pipeline inspection cameras to detect cracks, corrosion, and leaks. We combine this with pressure and flow testing for both pressurized and gravity-fed systems, along with laser or sonar profiling to identify deformation or sediment buildup.

This comprehensive, multi-method approach helps determine whether pipeline relining, structural pipe lining, or full replacement is the best solution for your specific situation. The data we collect provides clear evidence of your pipeline’s current condition and helps forecast its remaining service life.

Understanding Your Options: Repair, Rehabilitation, or Replacement

Not all pipelines need replacement. In many cases, trenchless pipeline experts can restore systems to like-new condition using modern rehabilitation techniques. The key is matching the right solution to your pipeline’s specific condition and performance requirements.

Spot repairs work well for isolated damage and include FRP (Fiber-Reinforced Polymer) patches, internal joint seals, or CIPP spot repairs. These targeted fixes address specific problem areas without requiring full-length rehabilitation, making them cost-effective for pipelines that are otherwise in good condition.

Full-length rehabilitation becomes necessary when damage is widespread or when you need to improve the entire system’s structural integrity. CIPP lining creates a seamless new pipe within your existing pipeline, while SIPP epoxy coating provides exceptional corrosion protection for potable water systems. For high-pressure pipelines, our Primus Line® technology delivers superior strength and longevity without excavation.

Complete replacement is sometimes unavoidable, particularly when pipes are collapsed, severely misaligned, or structurally unstable beyond repair. Even in these scenarios, sliplining and other no-dig technology methods may be possible and significantly reduce disruption compared to traditional open-cut construction, protecting roads, landscaping, and daily operations.

The Cost of Making the Wrong Decision

Choosing the wrong approach carries significant consequences. Unnecessary pipe replacement can inflate project costs by hundreds of thousands or even millions of dollars when pipe rehabilitation would have sufficed. On the other hand, ignoring early warning signs or attempting repairs on pipelines that need replacement can trigger emergency shutdowns, service interruptions, and customer complaints.

Pipeline failures also increase the risk of environmental contamination and regulatory penalties. In water and wastewater systems, these failures can affect public health and safety, making accurate assessment and appropriate action critical.

That’s why Advantage Reline Solutions delivers evidence-based recommendations backed by thorough inspections and decades of combined experience.

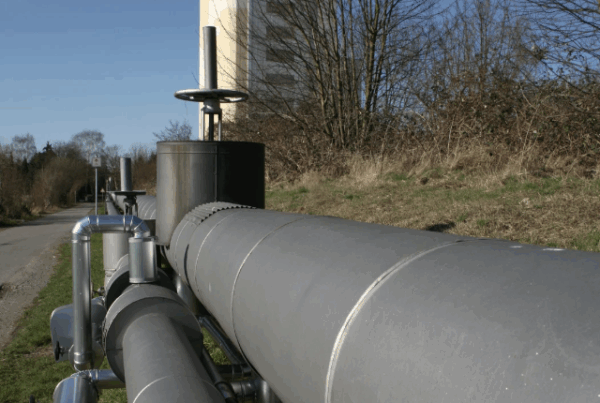

Trenchless Technology: Minimizing Disruption While Maximizing Results

Our trenchless rehabilitation methods restore pipeline integrity without the extensive excavation that disrupts communities and businesses.

- The Primus Line® Pipe Liner System handles pressurized water mains and industrial pipelines with exceptional strength-to-weight ratios.

- CIPP (Cured-in-Place Pipe) excels in wastewater rehabilitation and stormwater infrastructure, creating a seamless, corrosion-resistant barrier.

- SIPP (Sprayed-in-Place Pipe) provides superior corrosion protection for potable water pipe repair while maintaining full flow capacity.

These underground pipeline solutions extend service life by 50 years or more with minimal downtime. Your roads remain intact, landscaping stays undisturbed, and urban areas continue functioning normally during installation. The result is cost-effective pipeline rehabilitation that balances performance, compliance, and sustainability.

Partner with Advantage Reline for Expert Pipeline Solutions

We provide comprehensive pipeline rehabilitation that considers your entire infrastructure investment. Our team evaluates structural integrity, remaining service life, budget constraints, and long-term performance goals to recommend the most appropriate solution.

Whether you need municipal pipeline services, commercial pipeline rehabilitation, or emergency pipeline repair, Advantage Reline delivers trenchless pipeline expertise across North America. Our certified technicians and proven methodologies ensure your project meets industry standards while staying on schedule and within budget.

Get Your Pipeline Assessed Today

Leaks, backups, reduced flow capacity, or discolored water are warning signs that shouldn’t be ignored. Don’t wait for a catastrophic failure that forces emergency response and inflates costs.

Contact Advantage Reline today for a comprehensive pipeline inspection.

We’ll provide clear documentation of your pipeline’s condition and recommend the right solution—whether that’s targeted repair, trenchless rehabilitation, or full replacement—to keep your infrastructure reliable for decades to come.